Articles

FURNACE IMPROVEMENTS THAT WORK

In the competitive landscape of aluminum production, operational efficiency isn't just a goal—it's a necessity. This article explores the transformative impact of adopting advanced furnace technologies and enhancements in aluminum foundries.

Furnace Data Integration

One fact stands out in my travels across North America, examining processes of all shapes and sizes: melt shops are frequently overlooked in technological advancements. Casting or machining a part faster garners the most attention and excitement, neglecting the foundational melting process, which has significant potential to improve outcomes. Watching how excited personnel are to try the latest in coolants to increase the throughput and efficiency of the finished part, I often think – Why is it that the melting process lacks this kind of attention?

Dedicated Support For Foundry Operations

The Schaefer Group's recent collaborative effort with TST Inc. in advancing aluminum technology has been featured in Light Metal Age! The feature showcases our commitment to advancing technology and fostering a strong, productive relationship with our clients.

Our recent project with TST Inc., involving the trial of the MagPump technology. Our experts were on-site, providing hands-on coordination and oversight, ensuring the MagPump's seamless integration and operation.

Download PDF: Click here to view the article.

Determining a Customer's Needs to Achieve Objectives & Goals

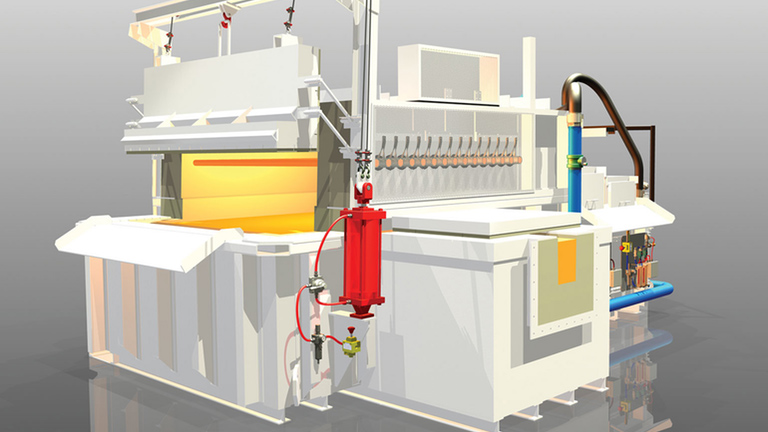

One of the most frequent questions we get asked is, "What is the right furnace for my operation?" While we understand you are making aluminum castings either by die casting, permanent mold, sand castings, tilt pour, investment casting, or lost foam—much more needs to be known to properly support your production facility.

Download PDF: Click here to view the article.

How To Protect Personnel in Melting Operations

Wearing the proper protective apparel and equipment when working near molten aluminum is extremely important in preventing injury to production workers. It could mean the difference between life and serious injury/or death.

Download PDF: Click here to view the article.

Crucible Melting Furnaces Operation Guidelines

Let me start by saying that if you are comfortable using crucible furnaces—then you might not know how much they truly cost. With worker comfort issues, maintenance, crucible bowl costs, downtime, reline costs, and workers comp or safety costs associated with these units, they can cost more than the dollars saved in space, metal inventory (3 to 1 hold to melt ratio), and lower upfront costs.

Download PDF: Click here to view the article.

Furnace Facts, ROI's & Energy Use Numbers

In this article we will give you some basic facts about melting and holding aluminum in everyday furnaces as well as a ranking of ROI on improvements you can make to those furnaces to increase efficiency and energy usage is a number of different types of furnaces.

Download PDF: Click here to view the article.

Why You Need A Systems Integrator

Metalcasting productivity relies on access to – and application of – the best process data, and to achieve that it’s necessary to gain the expertise for selecting and implementing the right process technology.

Download PDF: Click here to view the article.

Aluminum Metal is Still More Expensive Than Energy

With energy prices scheduled to rise 30% in the next two years, foundries are looking for ways to reduce wasted energy and materials in their manufacturing process.

Download PDF: Click here to view the article.

Understanding the Challenges With Electric Crucible Furnaces

A lot of companies use electric crucibles for plenty of good reasons (especially space saving). However, sometimes we see foundries using them, because that’s all they are accustomed to operating. We believe that if they did a careful evaluation of all of the high energy and labor costs that they would take a harder look at ways to reduce those costs.

Download PDF: Click here to view the article.

Defect Prevention With a World Class Melt Shop

One of the best ways to optimize defect prevention is to offer your casting process world-class melt quality. So many companies have lost focus on what is the most important element in the casting process, the quality of melt they have in the dip well.

Download PDF: Click here to view the article.

When Choosing an Aluminum Melting Furnace

One of the most frequent questions we get asked is: what is the right furnace for my operation? Our next step is to ask questions to get to the heart of what it is you are trying to do. Yes, we know you are trying to make an aluminum casting either by die casting, permanent mold, sand castings, tilt pour, investment casting and of course lost foam. But other than making lots of parts, what are your goals for this casting?

Download PDF: Click here to view the article.

What Is Foundry 4.0?

Reprinted with permission of Penton Media, Inc.

Establishing smarter, more efficient manufacturing using communication technologies that allow the plant and its constituent processes to run autonomously.

Read More: Click here to view the article.

How Do I Choose the Right Aluminum Furnace?

Reprinted with permission from the North America Die Casting Association, publishers of Die Casting Engineer

The first question any salesperson should ask is, “What are your goals for this project?” Is it highest quality metal, low upfront costs, energy cost, metal melt loss, safety? Prioritize these items and then look at what best fits your goals. Also, items furnace manufactures need to know are... what alloy are you using, what temperature do you want to cast your parts and are you modifying the alloy in any way? Do you want to melt chips or recover inserts from your parts? Once we have this information and your plant layout, we can better recommend what type of furnace best fits your plant and goals.

Download PDF: Click here to view the article.

Foundry 4.0 What Is It?

The first thing to understand about Industry 4.0 is it is not one technology but a combination of modern technologies combined to create a ‘SMART factory.’ The 4.0 stands for the fourth industrial revolution which at first sounds extreme but when you start to look at the possibilities, it is easy to see how these technologies can become real game-changers. Industry or Foundry 4.0 is the brainchild of the German government, and the train of thought is to create smarter, more efficient manufacturing through the use of SMART factories in the not too distant future. This will be achieved by various technologies communicating in a way that allows autonomous running of the facility and processes.

Download PDF: Click here to view the article.

Virtual Reality In Manufacturing - The Time Is Now

Virtual Reality (VR) answers the question to so many manufacturing’s challenges from eliminating rework on the factory floor to proper training in dangerous environments— VR is proving to be a game changer in the manufacturing world.

As the only global aluminum furnace manufacturer that is using this technology, we can proudly attest to the many benefits of VR.

Download PDF: Click here to view the article.

Benefits of Taking Your Melt Area into the 21st Century - (Simple Solutions That Work! September, 2018)

As I travel around the world seeing processes of all shapes and sizes, one thing becomes very clear – that melt shops are most often left out of any and all of the latest technology improvements.

Download PDF: Click here to view the article.

Molten Metal Management Back to Basics - (Simple Solutions That Work! April, 2018)

In my 37 years of traveling all over the world one thing has become increasingly apparent. Some die casters and foundries have lost the basic understanding of molten metal management. I have been asked to talk to companies about this subject more in the last three years than in all years combined with The Schaefer Group, Inc.

Download PDF: Click here to view the article.

Get Back to the Basics of Melting - (Foundry Management & Technology January 2018)

Reprinted with permission of Penton Media, Inc.

For aluminum foundries and diecasters, establishing the right processes will achieve high-quality metal consistently, improving results and reducing waste.

Download PDF: Click here to view the article.

Furnace Facts, ROI’s & Energy Use Numbers - (Simple Solutions That Work! September, 2017)

The ‘Ranking of ROI’ expenditures for aluminum furnaces, in other words, how to get the biggest bang for your bucks from quickest-to-slowest investment recovery.

Download PDF: Click here to view the article.

Why You Nees a Systems Integrator - (Simple Solutions That Work! April, 2017)

Where can you find someone who understands the data you need and how to display, capture and store it forever?

Download PDF: Click here to view the article.

Electrically Heated Immersion Element Holding Furnaces - (Simple Solutions That Work! Sept, 2016)

Immersion element aluminum holding furnaces available for over 10 years and are finally gaining in popularity with North American manufacturers. Asian companies were the first to use them in the US and now they have really taken off in the die cast and foundry world for important energy efficient, clean metal producing, and low maintenance reasons...

Download PDF: Click here to view the article.