News & Events

News

- AFS Metalcasting Congress is Here!

- The Schaefer Group is Heading to NADCA South

- Furnace Data Integration

- 3 Tips to Extend the Life of Your Furnace

- Visit Us at the TMS 2024 Annual Meeting and Exhibition

- Refractory Sales & Service

- Introducing Jeff Zurface, Our New National Sales Manager

- Wishing you a Merry Christmas and a Happy New Year

- Dedicated Support For Foundry Operations

- Honoring Dick Schaefer

- Determining A Customer’s Needs to Achieve Objectives & Goals

- Visit Us at NADCA 2023

- Determining a Customer's Needs to Achieve Objectives & Goals

- Keep Your Furnaces Clean and Burning Smoothly

- How To Protect Personnel in Melting Operations

- High-Performing Stack/Tower Melters

- VISIT US AT AFS METALCASTING CONGRESS

- How To Protect Personnel in Melting Operations

- Custom Powered Transfer Ladles & Ladle Heaters For Efficient Foundry Operations

- Visit us at Euroguss Mexico

- Refractory Contracting, Materials, & Training

- Merry Christmas from The Schaefer Group

- 2022 Excellence in Safety

- Visit Us At FUNDIEXPO Monterrey 2022

- Visit Us At NADCA 2022

- Crucible Melting Furnaces Operation Guidelines

- Now Offering High Performing Stack/ Tower Melters

- Visit Us at the Aluminum Extrusion Show In Orlando

- Furnace Facts, ROI's & Energy Use Numbers

- VISIT US AT CASTEXPO 2022

- Visit us at Mexico's Manufacturing Supply Chain Summit

- Merry Christmas & Happy New Year!

- Aluminum Metal is Still More Expensive Than Energy

- VISIT US AT NADCA 2021

- Visit Us At Aluminum USA

- Understanding the Challenges With Electric Crucible Furnaces

- Merry Christmas & Happy New Year!

- Sorry we missed you at the recent NADCA Die Casting Congress and Tabletop

- Defect Prevention With a World Class Melt Shop

- Aluminum Furnace Cleaning Care Recommendations

- When Choosing an Aluminum Melting Furnace

- Foundry 4.0 What Is It?

- 2019 Doehler Award Winner

- Virtual Reality In Manufacturing - The Time Is Now

- The Schaefer Group Announces New Division Office

- Benefits of Taking Your Melt Area into the 21st Century - (Simple Solutions That Work! September, 2018)

- Molten Metal Management Back to Basics - (Simple Solutions That Work! April, 2018)

- Get Back to the Basics of Melting

- Furnace Facts, ROI’s & Energy Use Numbers - (Simple Solutions That Work! September, 2017)

- Why You Nees a Systems Integrator - (Simple Solutions That Work! April, 2017)

- Electrically Heated Immersion Element Holding Furnaces - (Simple Solutions That Work! Sept, 2016)

- Epcor Foundry Installs Schaefer Furnace

Events

Awards

News

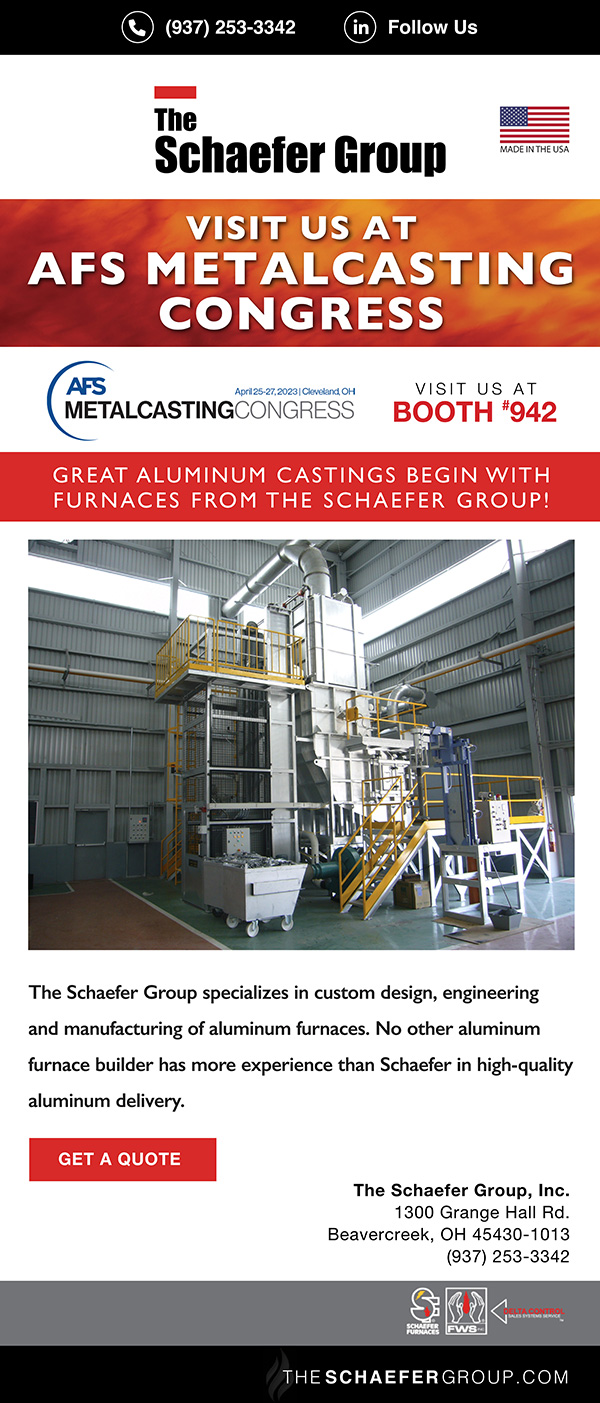

AFS Metalcasting Congress is Here!

Visit Us at the AFS Metal Casting Congress in Milwaukee, WI | April 23-25 | Booth #845

North America's premier event for the full metalcasting supply chain is coming to Milwaukee's Baird Center April 23-25. Metalcasting Congress combines the best in learning, networking, and product exploration. Experience in-depth technical sessions on the latest industry advancements to keep you ahead of the trends.

We hope to see you at AFS this year where we will showcase our custom aluminum furnaces for die casting, permanent mold, and sand foundries. Our team of experts will be on-site to answer all your questions and provide solutions to your unique challenges.

The Schaefer Group is the most comprehensive equipment and capabilities line-up, dedicated to serving the foundry industry.

- Custom Designed Furnaces and Systems

- Electric Aluminum Melting Furnaces

- Gas, Oil or Propane Aluminum Furnaces

- Low Pressure Die Casting Systems

The Schaefer Group is Heading to NADCA South

Visit Us at the NADCA South Die Casting Expo in Monterrey, MX | April (Abril)17-19 | Booth #56

No other aluminum furnace builder has more experience than Schaefer in high-quality aluminum delivery.

Stop by booth # to learn about our latest projects. The Schaefer Group specializes in custom design, engineering, and manufacturing aluminum furnaces.

Our team of experts will be on-site to answer all your questions and provide solutions to your unique challenges.

Furnace Data Integration

One fact stands out in my travels across North America, examining processes of all shapes and sizes: melt shops are frequently overlooked in technological advancements. Casting or machining a part faster garners the most attention and excitement, neglecting the foundational melting process, which has significant potential to improve outcomes. Watching how excited personnel are to try the latest in coolants to increase the throughput and efficiency of the finished part, I often think – Why is it that the melting process lacks this kind of attention?

Download PDF: Click here to view the article.

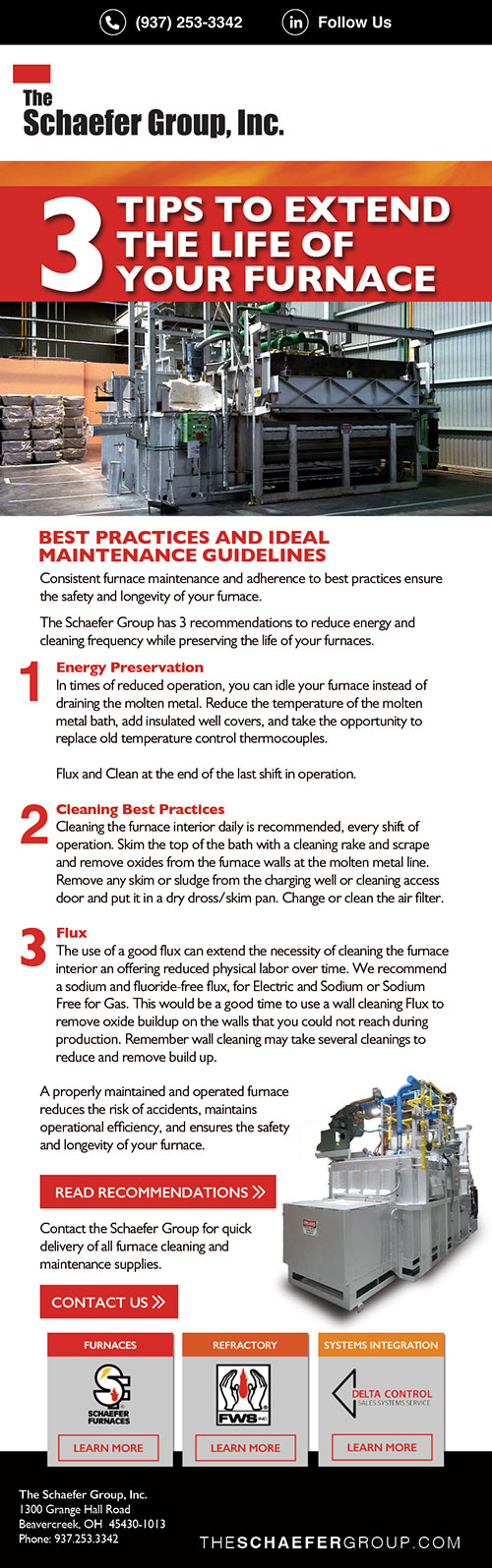

3 Tips to Extend the Life of Your Furnace

Best practices and ideal maintenance guidelines

Consistent furnace maintenance and adherence to best practices ensure the safety and longevity of your furnace. The Schaefer Group has 3 recommendations to reduce energy and cleaning frequency while preserving the life of your furnaces.

- Energy Preservation

In times of reduced operation, you can idle your furnace instead of draining the molten metal. Reduce the temperature of the molten metal bath, add insulated well covers, and take the opportunity to replace old temperature control thermocouples. - Cleaning Best Practices

Cleaning the furnace interior daily is recommended, but at a minimum, clean 1-2x weekly. Skim the top of the bath with a cleaning hoe tool and scrape and remove oxides from the furnace walls at the molten metal line. Remove any skim or sludge from the charging well or cleaning access door and put it in a dry dross/skim pan. Change or clean the air filter. - Cover Flux

The use of a good cover flux can extend the necessity of cleaning the furnace interior to once per week. We recommend a sodium and fluoride-free fused flux, like Al-Clean F216. This would be a good time to use a wall cleaning flux to remove oxide buildup on the walls that you could not reach during production.

A properly maintained and operated furnace reduces the risk of accidents, maintains operational efficiency, and ensures the safety and longevity of your furnace.

Visit Us at the TMS 2024 Annual Meeting and Exhibition

Hyatt Regency Orlando | Orlando, Florida

March 3rd - 7th, 2024

Booth #102

The Schaefer Group, Inc. provides both standard inventory and custom pre-cast components and shapes, including:

- Runners

- Funnels

- Pouring Components

- Covers

Large, intricate custom pieces have firing capabilities of up to 2,000 °F. We maintain a sizable inventory for immediate shipping.

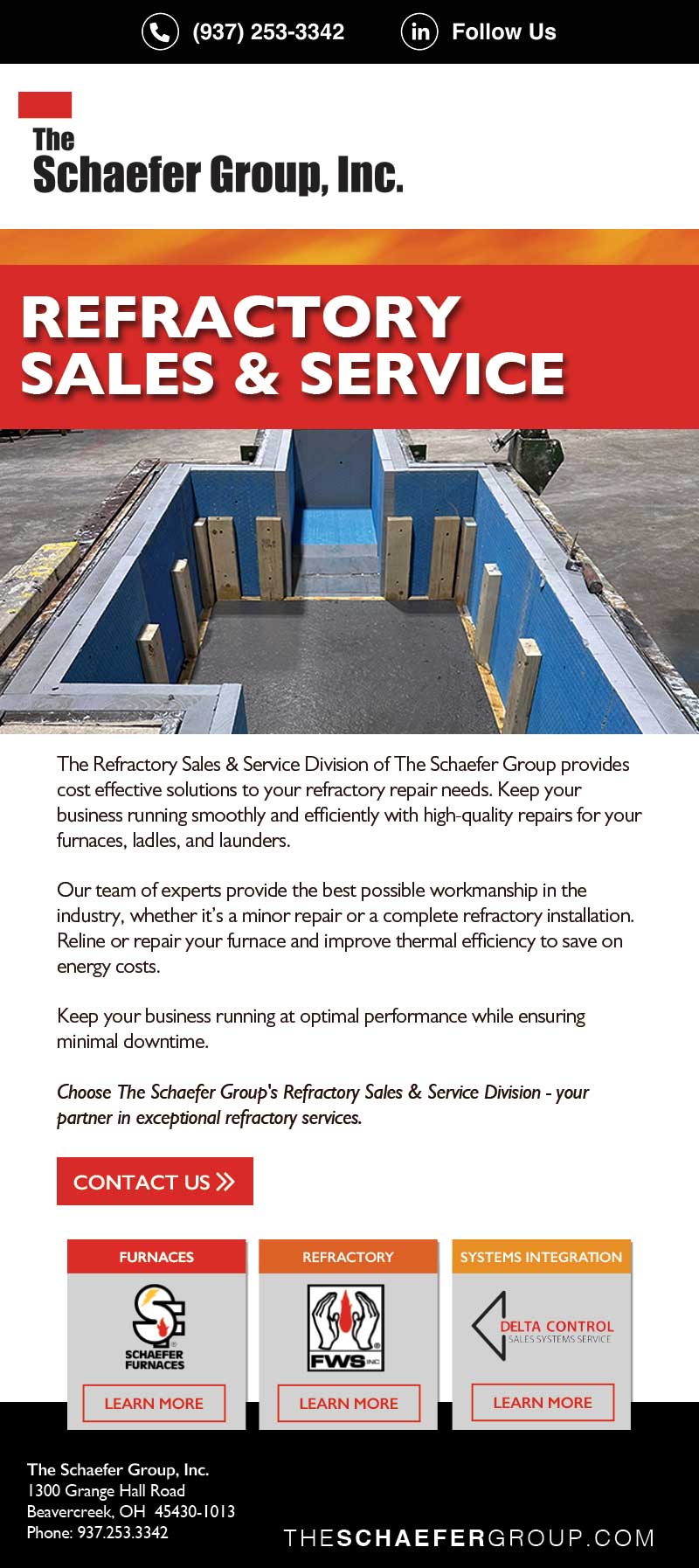

Refractory Sales & Service

The Refractory Sales & Service Division of The Schaefer Group provides cost effective solutions to your refractory repair needs. Keep your business running smoothly and efficiently with high-quality repairs for your furnaces, ladles, and launders.

Our team of experts provide the best possible workmanship in the industry, whether it's a minor repair or a complete refractory installation. Reline or repair your furnace and improve thermal efficiency to save on energy costs.

Keep your business running at optimal performance while ensuring minimal downtime.

Choose The Schaefer Group's Refractory Sales & Service Division - your partner in exceptional refractory services.

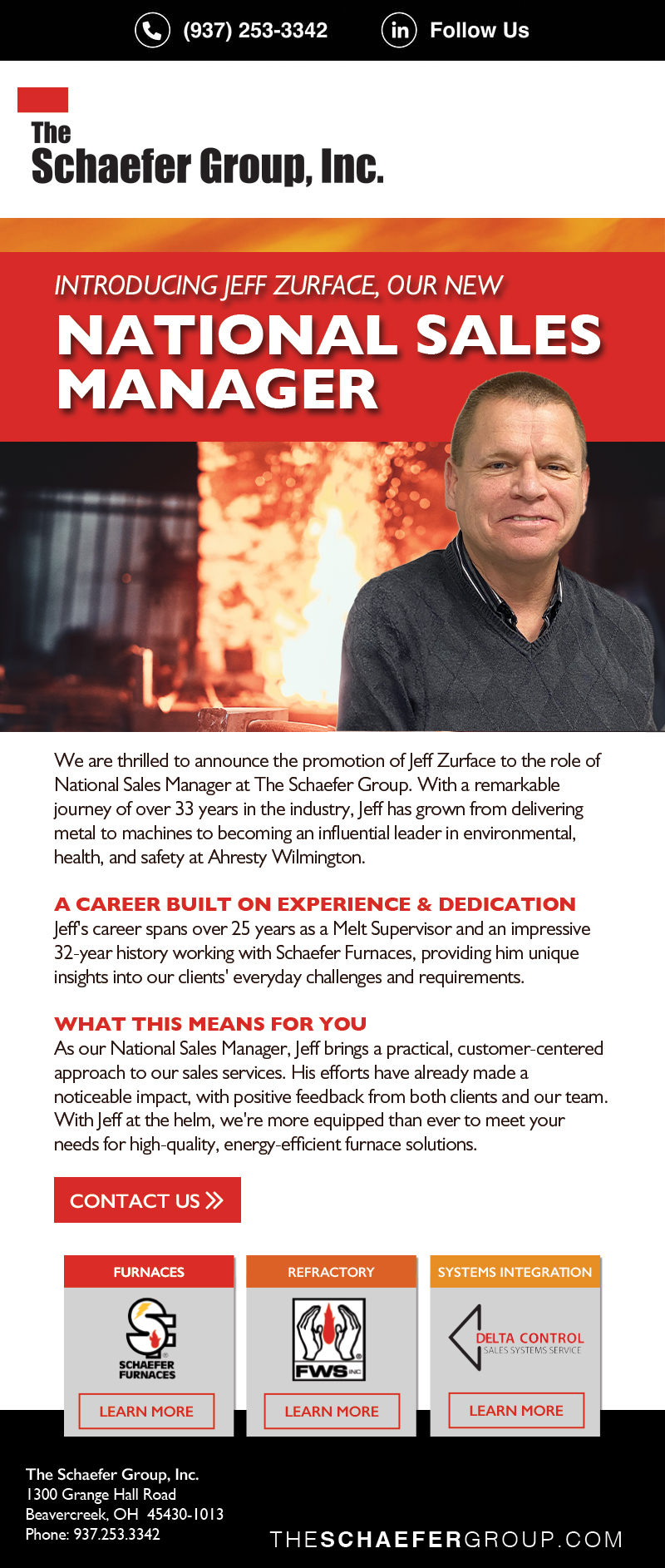

Introducing Jeff Zurface, Our New National Sales Manager

We are thrilled to announce the promotion of Jeff Zurface to the role of National Sales Manager at The Schaefer Group. With a remarkable journey of over 33 years in the industry, Jeff has grown from delivering metal to machines to becoming an influential leader in environmental, health, and safety at Ahresty Wilmington.

A Career Built on Experience and Dedication

Jeff's career spans over 25 years as a Melt Supervisor and an impressive 32-year history working with Schaefer Furnaces, providing him unique insights into our clients' everyday challenges and requirements.

What This Means for You

As our National Sales Manager, Jeff brings a practical, customer-centered approach to our sales services. His efforts have already made a noticeable impact, with positive feedback from both clients and our team. With Jeff at the helm, we're more equipped than ever to meet your needs for high-quality, energy-efficient furnace solutions.

Dedicated Support For Foundry Operations

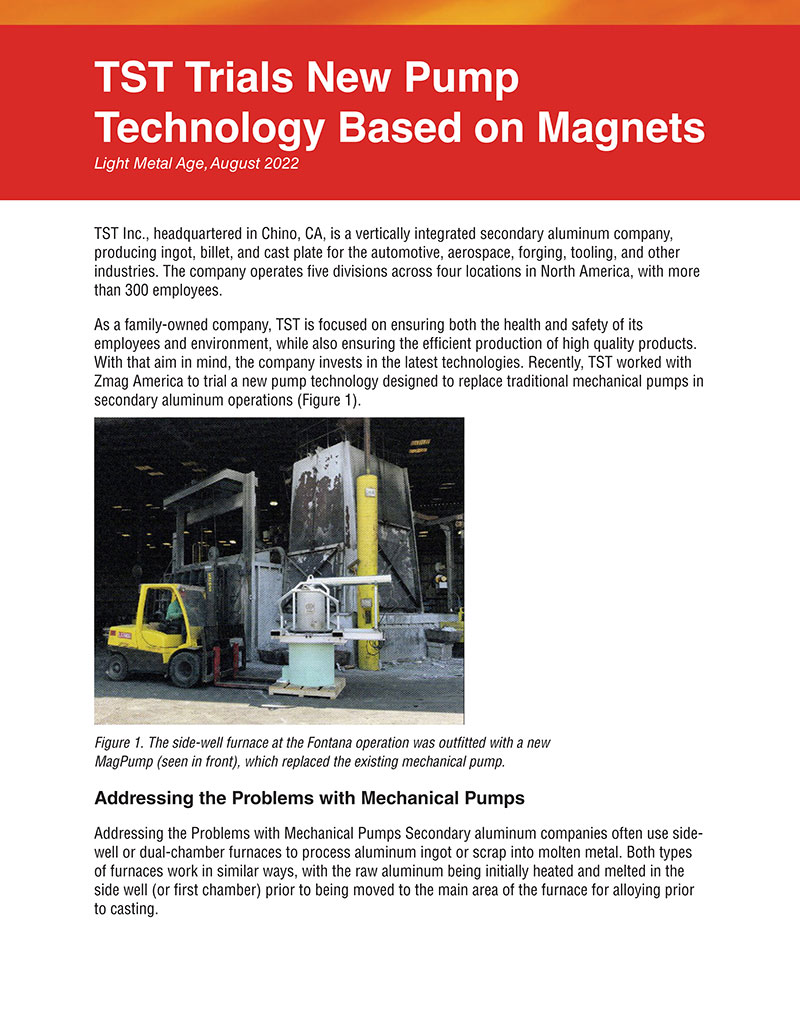

The Schaefer Group's recent collaborative effort with TST Inc. in advancing aluminum technology has been featured in Light Metal Age! The feature showcases our commitment to advancing technology and fostering a strong, productive relationship with our clients.

Our recent project with TST Inc., involving the trial of the MagPump technology. Our experts were on-site, providing hands-on coordination and oversight, ensuring the MagPump's seamless integration and operation.

Download PDF: Click here to view the article.

Honoring Dick Schaefer

We are saddened to announce the passing of Richard “Dick” Schaefer, a cornerstone of The Schaefer Group family and a beloved figure in our industry. The Schaefer legacy, which blossomed from the foundations of Frank W. Schaefer, Inc., owes much of its growth and current stature to Dick's relentless dedication and visionary leadership. Starting as a laborer, Dick’s growth to a seasoned executive and owner showcased his innate ability to innovate and lead. As a President and CEO, Dick Schaefer spearheaded the expansion into three distinct yet interlinked divisions: Schaefer Furnaces Inc., FWS Inc., and Delta Controls. His nurturing and mentorship of countless managers, engineers, sales personnel, and office staff have left indelible marks, making our organization not just a place of work but a community of like-minded individuals aspiring for greatness.

In 2016, Dick began transferring leadership to David Nelson and David Robinson, moving to the position of Chairman. His visionary leadership was acknowledged far and wide, and in 2019, he was honored with the prestigious Herman Doehler Award by the North American Die Cast Association.

Dick’s funeral visitation service will be on Friday, October 20th, 2023. More information can be found here

We extend our condolences to the Schaefer family and invite you to join us in honoring Dick’s legacy.

Determining A Customer’s Needs to Achieve Objectives & Goals

One of the most frequent questions we get asked is, "What is the right furnace for my operation?" While we understand you are making aluminum castings either by die casting, permanent mold, sand castings, tilt pour, investment casting, or lost foam—much more needs to be known to properly support your production facility.

Visit Us at NADCA 2023

Great aluminum castings begin with furnaces from the Schaefer Group!

The Schaefer Group specializes in custom design, engineering, and manufacturing aluminum furnaces. No other aluminum furnace builder has more experience than Schaefer in high-quality aluminum delivery. Stop by booth #311 to learn about our latest projects!

Grand Rapids, MI

September 19-21

Booth #311

Determining a Customer's Needs to Achieve Objectives & Goals

One of the most frequent questions we get asked is, "What is the right furnace for my operation?" While we understand you are making aluminum castings either by die casting, permanent mold, sand castings, tilt pour, investment casting, or lost foam—much more needs to be known to properly support your production facility.

Download PDF: Click here to view the article.

Keep Your Furnaces Clean and Burning Smoothly

The Schaefer Group, Inc. knows that your furnaces are the burning heart of your business. That’s why we offer the flux options you need to keep them running clean and smoothly.

The Benefits of our SGI Fluxes Include

- Reduced melt loss

- Reduction of inclusions

- Improved fluidity

- Improved melt efficiency

- Less furnace cleaning time

- Lower hydrogen

Types of Fluxes We Offer

When it comes to your business, you have specific needs – not a one size fits all solution.

Our flux options were designed with you in mind and include:

- Schaefer’s Super Cover Salt – removes alkali metals and nonmetallic inclusions from liquid aluminum.

- SGI-Therm X Salt – prevents the exothermic reactions of the dross in dross pans which can lead to metal loss.

- SGI-101 – can be used as a broadcast flux or injected as a desludging flux designed to melt and react at furnace temperature ranges from 680-760°C (1250-1400°F).

- SGI-106 – is a low-temperature flux that melts and reacts exothermically at furnace temperature ranges from 660-730°C (1225-1350°F).

- SGI-126 – reacts exothermically and melts aluminum trapped in the oxide build-up along the metal line on the furnace walls.

- SGI-209 – is a sodium-free flux that melts and reacts at furnace temperature ranges from 690-800°C (1275-1450°F).

- SGI-F216 – also removes alkali metals and nonmetallic inclusions from liquid aluminum.

Flux Training

We can provide flux recommendations for your company and train your furnace tenders so you get the most out of your product. Furnace operators that have been adequately trained and given the correct flux and tools can shorten the time needed to clean your furnace and reduce the damage to the refractory lining.

The Schaefer Group, Inc. provides turn-key service, from design and installation to complete technical support and maintenance. Contact a Schaefer Group representative for a complete list of tools available to maintain your furnace properly.

How To Protect Personnel in Melting Operations

Wearing the proper protective apparel and equipment when working near molten aluminum is extremely important in preventing injury to production workers. It could mean the difference between life and serious injury/or death.

High-Performing Stack/Tower Melters

In partnership with Sanken Sangyo of Japan, The Schaefer Group offers a full line of stack/ tower melters ranging from small in-cell melters from 600 lbs./hr. to large central melt furnaces up to 15,000 lbs./hr.

- Designed to melt scrap/chips, degassing/filtration and more

- Reduce Metal Loss – 98% yields

- Simple operation and ease of maintenance

- Compact footprint – 1/3 of conventional space

- Energy savings up to 25%

- Environmentally friendly – less exhaust, chips and scattering

How To Protect Personnel in Melting Operations

Wearing the proper protective apparel and equipment when working near molten aluminum is extremely important in preventing injury to production workers. It could mean the difference between life and serious injury/or death.

Download PDF: Click here to view the article.

Custom Powered Transfer Ladles & Ladle Heaters For Efficient Foundry Operations

Schaefer offers custom-powered transfer ladles and ladle heaters to optimize your foundry transport operations.

Our equipment is designed with ruggedness and simplicity in mind, ensuring a long production life and easy operation.

The Schaefer Heatflow Program is designed to show energy cost savings using a specialized flexliner that will ensure reduced metal temperature loss during transport, lower thermal head temperatures necessary in aluminum melt furnaces, reduce time and energy requirements and reduce lining maintenance.

Powered Transfer Ladles

- Available in standard sizes of 1,000 lb, 1,500 lb, and 2,000 lb holding capacities for molten aluminum

- Custom-built ladles for aluminum, zinc, or other metal transport

- Offer a range of power options, barrel designs, single or multiple spout designs, and transport options

- Compatible with a variety of forklifts, truck transporters, or monorails for easy movement

Ladle Heaters

- Designed according to the size of the ladle and the alloy you are heating

- Typical burner rating range of 100,000 BTUs to 1,750,000 BTUs

- Regulated gas supply of ½ lb to 1lb, air supply regulated at 60 p.s.i. at 10 c.f.m., and power supply of 120V AC @ 30 amps

- Fully automatic unit with proximity switches, Siemens actuator valves, Honeywell controllers and flame safeties

Our custom-powered transfer ladles and ladle heaters are versatile and meet the needs of various metal casters, die casters, and foundries around the world. Contact us to learn more and to receive a quote

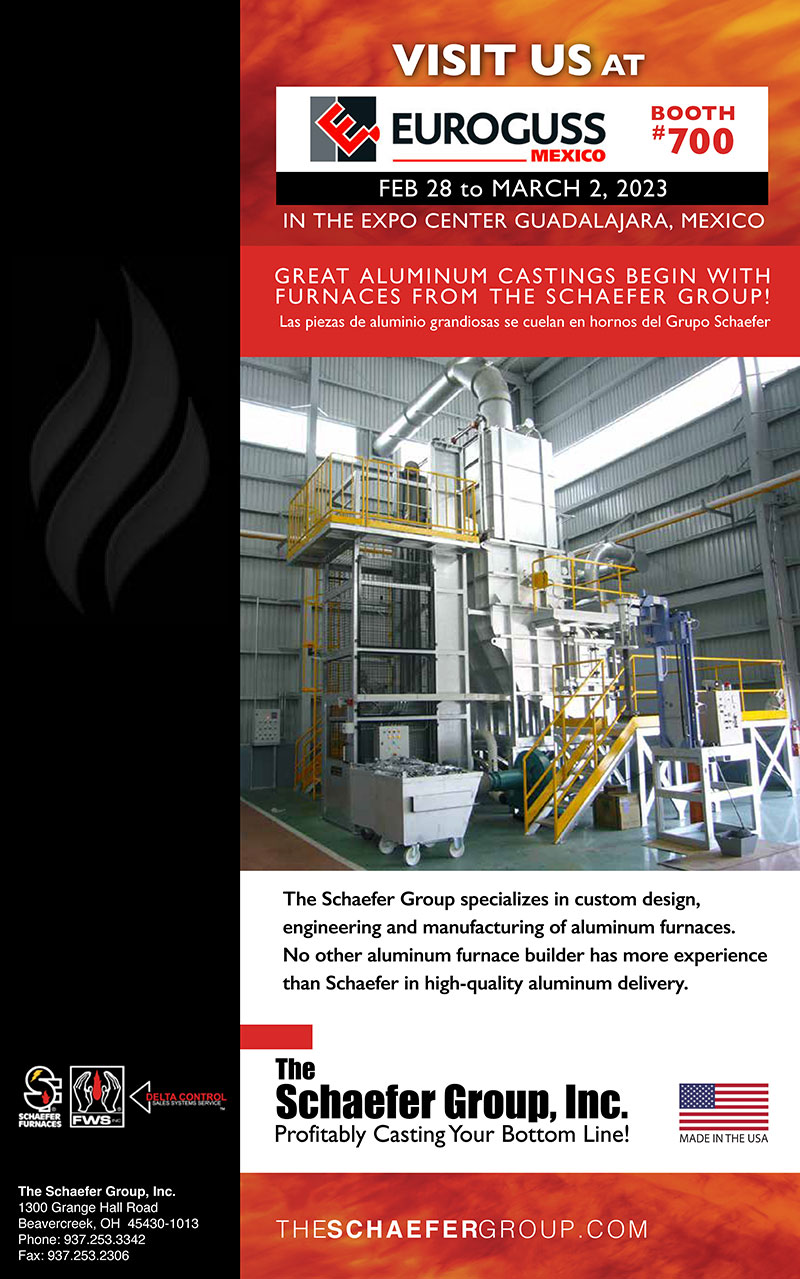

Visit us at Euroguss Mexico

Feb 28 to March 2, 2023

Expo Center Guadalajara, Mexico

BOOTH #700

REFRACTORY CONTRACTING, MATERIALS, & TRAINING

Trust FWS for top-notch refractory solutions 24/7, whether it's a full package, furnace reline, or rebuild. Our engineering expertise, extensive experience, and cutting-edge materials guarantee a quality project.

Services include:

- Complete design & engineering

- Turnkey installation

- High-quality refractory materials with options for premium & energy-efficient products

- Experienced workforce with decades in the aluminum industry

- On-site or in-shop services available anytime.

REFRACTORY MATERIALS

FWS distributes the highest quality refractory materials available, including Thermbond®, Plibrico® and Unifrax®. Not only can we reline your furnaces using any of these products, but we can also utilize any materials you specify.

- Ceramic Fiber Products – Blanket, Board, Paper, Modules & Specialties

- Monolithic Refractories – Dense & Insulating Castable, Plastic, Gunning & Shotcrete

- Firebrick & Mortar - Dense & Insulating Firebrick, High Alumina Mortar & Coating Mixes

- Block Insulation, Ceramic & Stainless-Steel Anchors, Precast Shapes

Other Materials – Concrete Patch Materials, Wear Ceramics, Pre-Krete Corrosion Resistant Linings

- Plastics – Gunite and Castable

- Mixes, Bonding Agents and Mortars

- Dense & Insulating Firebrick and Acid Bricks

- Coatings

- RCF Blankets and Board

- Phoscrete Hot Floor

RELINE, REPAIR SERVICES, AND MATERIALS

- Boilers

- Hot Water Tanks

- Incinerators

- Iron & Steel – Heat Treat

TRAINING

- Furnace Cleaning & Fluxing, Combustion System Troubleshooting.

- New Control Panels & Upgrades – HMI & PLC Programming.

- Combustion System Balancing and Fine Tuning

- Refractory Supervision, Heat Flow Analysis, Energy Audits.

Merry Christmas & Happy New Year

¡Feliz Navidad & Próspero Año Nuevo!

The Schaefer Group will be closed Monday, December 26th and Monday, January 2nd, 2023.

2022 Excellence in Safety

The Schaefer Group is honored to receive the 2022 Auman Excellence in Safety Award – Gold Level.

The Dayton Area Chamber of Commerce presented the award at the 70th Annual Safety Conference and Symposium in recognition of our exemplary safety programs and exceptional safety performance. The award is named the Auman Excellence in Safety Award in honor of Gary Auman, who chaired the Safety Conference for the last 20 years and has involvement in the Safety Steering Committee for 40 years.

The Schaefer Group is grateful for the efforts of Scott Maher, Director of Environmental Health and Safety/DOT, and the entire team at The Schaefer Group for keeping safety a core value of our organization.

Congratulations to the other 2022 Auman Excellence in Safety Award Winners.

The Full List of Award Winners

Scoring at Silver Level:

- Procter & Gamble Dayton Mixing Center

- Senior Resource Connection

Scoring at Gold Level:

- Davis H. Elliot Company, Inc.

- Lewis & Michael

- Norwood Medical

- Nurses Care Inc.

- PSC Crane & Rigging

- The Schaefer Group, Inc.

Scoring at Platinum Level:

- Plating Technology, Inc.

- Think Patented

- CompuNet Clinical Laboratories

- MSD, Inc

- Shook Construction Company

Crucible Melting Furnaces Operation Guidelines

Let me start by saying that if you are comfortable using crucible furnaces—then you might not know how much they truly cost. With worker comfort issues, maintenance, crucible bowl costs, downtime, reline costs, and workers comp or safety costs associated with these units, they can cost more than the dollars saved in space, metal inventory (3 to 1 hold to melt ratio), and lower upfront costs.

Download PDF: Click here to view the article.

Now Offering High Performing Stack/ Tower Melters

In partnership with Sanken Sangyo of Japan, The Schaefer Group offers a full line of stack/ tower melters ranging from small in-cell melters from 600 lbs./hr. to large central melt furnaces up to 15,000 lbs./hr.

- Designed to melt scrap/chips, degassing/filtration and more

- Reduce Metal Loss – 98% yields

- Simple operation and ease of maintenance

- Compact footprint – 1/3 of conventional space

- Energy savings up to 25%

- Environmentally friendly – less exhaust, chips and scattering

VISIT US AT Aluminum Extrusion Technology Seminar and Exposition

HILTON ORLANDO

ORLANDO, FL

MAY 3 - 5, 2022

BOOTH #723

The Schaefer Group, Inc. provides both standard inventory and custom pre-cast components and shapes including:

- Runners

- Funnels

- Pouring Components

- Covers

Large, intricate custom pieces have firing capabilities up to 2,000°F.

We maintain a sizable inventory for immediate shipping. If you need assistance in tool design, our technical staff will work with you to create the perfect components for your operation.

Furnace Facts, ROI's & Energy Use Numbers

In this article we will give you some basic facts about melting and holding aluminum in everyday furnaces as well as a ranking of ROI on improvements you can make to those furnaces to increase efficiency and energy usage is a number of different types of furnaces.

Download PDF: Click here to view the article.

VISIT US AT CASTEXPO

Greater Columbus Convention Center

Columbus, OH

April 23-26, 2022

Booth #841

Visit us at Mexico's Manufacturing Supply Chain Summit

El Paso Convention Center

El Paso, TX

March 31, 2022

Stand #125

Merry Christmas & Happy New Year!

The Schaefer Group will be closed December 24th and 31st.

We will reopen on Monday, January 3rd, 2022.

Aluminum Metal is Still More Expensive Than Energy

With energy prices scheduled to rise 30% in the next two years, foundries are looking for ways to reduce wasted energy and materials in their manufacturing process.

Download PDF: Click here to view the article.

Visit Us At Aluminum USA

Kentucky International Convention Center

Louisville, KY

Sept 1 & 2

Booth #1207

Understanding the Challenges With Electric Crucible Furnaces

A lot of companies use electric crucibles for plenty of good reasons (especially space saving). However, sometimes we see foundries using them, because that’s all they are accustomed to operating. We believe that if they did a careful evaluation of all of the high energy and labor costs that they would take a harder look at ways to reduce those costs.

Download PDF: Click here to view the article.

Merry Christmas & Happy New Year!

¡Feliz Navidad & Próspero Año Nuevo!

The Schaefer Group will be closed December 25 and January 1.

We will reopen on Monday, January 4, 2021.

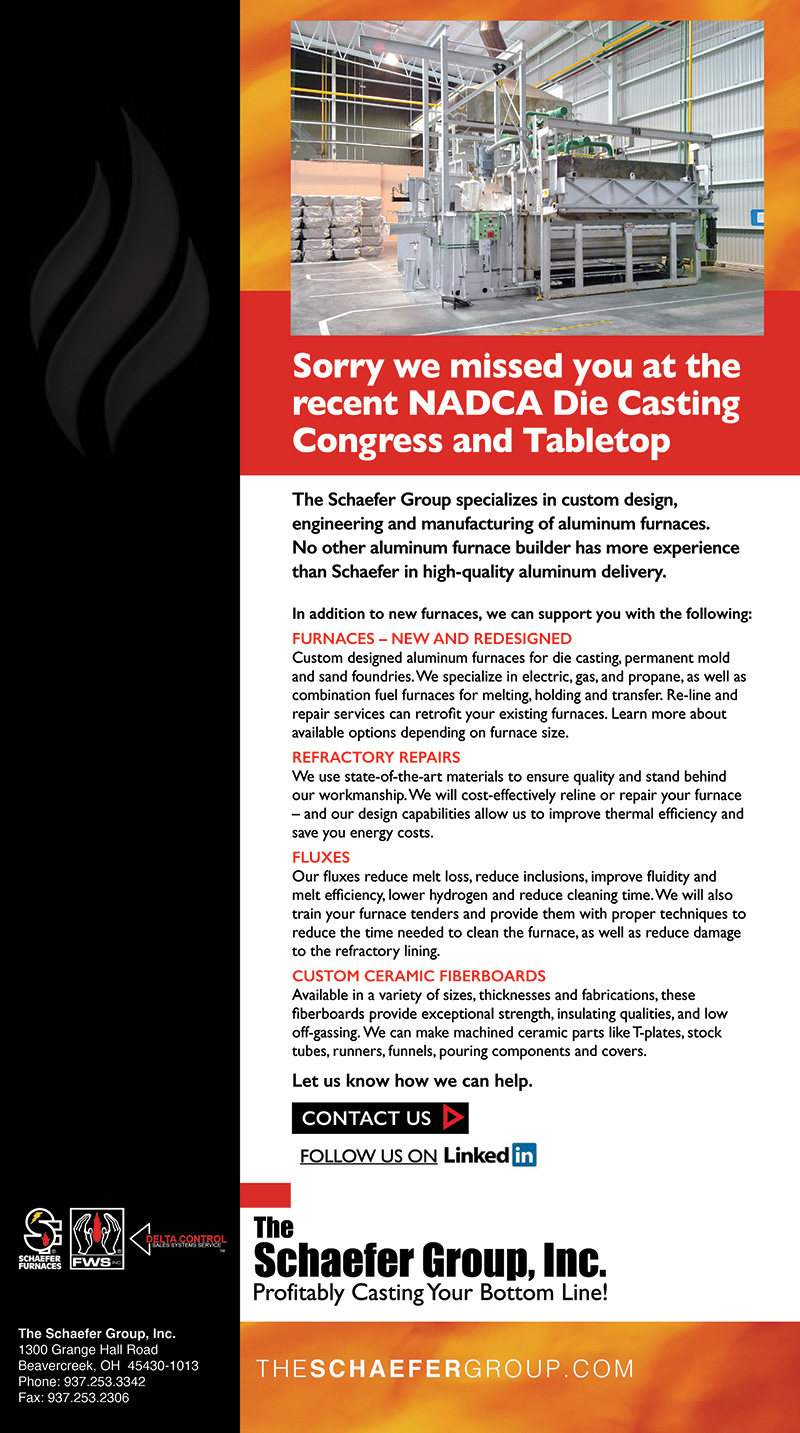

Sorry we missed you at the recent NADCA Die Casting Congress and Tabletop

The Schaefer Group specializes in custom design, engineering and manufacturing of aluminum furnaces. No other aluminum furnace builder has more experience than Schaefer in high-quality aluminum delivery.

In addition to new furnaces, we can support you with the following:

FURNACES – NEW AND REDESIGNED

The Schaefer Group specializes in custom designed aluminum furnaces for die casting, permanent mold and sand foundries. We specialize in electric, gas, and propane, as well as combination fuel furnaces for melting, holding and transfer. Re-line and repair services can retrofit your existing furnaces. Learn more about available options depending on furnace size.

REFRACTORY REPAIRS

We use state-of-the-art materials to ensure quality and stand behind our workmanship. We will cost-effectively reline or repair your furnace – and our design capabilities allow us to improve thermal efficiency and save you energy costs.

FLUXES

Our fluxes reduce melt loss, reduce inclusions, improve fluidity and melt efficiency, lower hydrogen and reduce cleaning time. We will also train your furnace tenders and provide them with proper techniques to reduce the time needed to clean the furnace, as well as reduce damage to the refractory lining.

CUSTOM CERAMIC FIBERBOARDS

Available in a variety of sizes, thicknesses and fabrications, these fiberboards provide exceptional strength, insulating qualities, and low off-gassing. We can make machined ceramic parts like T-plates, stock tubes, runners, funnels, pouring components and covers.

Let us know how we can help.

Contact Us

Defect Prevention With a World Class Melt Shop

One of the best ways to optimize defect prevention is to offer your casting process world-class melt quality. So many companies have lost focus on what is the most important element in the casting process, the quality of melt they have in the dip well.

Download PDF: Click here to view the article.

Aluminum Furnace Cleaning Care Recommendations

To help you care for your furnaces, The Schaefer Group has 3 recommendations to reduce your cleaning frequency while preserving the life of your furnaces.

Download PDF: Click here to view the Pdf

When Choosing an Aluminum Melting Furnace

One of the most frequent questions we get asked is: what is the right furnace for my operation? Our next step is to ask questions to get to the heart of what it is you are trying to do. Yes, we know you are trying to make an aluminum casting either by die casting, permanent mold, sand castings, tilt pour, investment casting and of course lost foam. But other than making lots of parts, what are your goals for this casting?

Download PDF: Click here to view the article.

Foundry 4.0 What Is It?

The first thing to understand about Industry 4.0 is it is not one technology but a combination of modern technologies combined to create a ‘SMART factory.’ The 4.0 stands for the fourth industrial revolution which at first sounds extreme but when you start to look at the possibilities, it is easy to see how these technologies can become real game-changers. Industry or Foundry 4.0 is the brainchild of the German government, and the train of thought is to create smarter, more efficient manufacturing through the use of SMART factories in the not too distant future. This will be achieved by various technologies communicating in a way that allows autonomous running of the facility and processes.

Download PDF: Click here to view the article.

2019 Doehler Award Winner

In recognition of outstanding contributions to the advancement of the die casting industry, NADCA presented Dick Schaefer with the prestigious 2019 Herman H. Doehler Award.

Virtual Reality In Manufacturing - The Time Is Now

Virtual Reality (VR) answers the question to so many manufacturing’s challenges from eliminating rework on the factory floor to proper training in dangerous environments— VR is proving to be a game changer in the manufacturing world.

As the only global aluminum furnace manufacturer that is using this technology, we can proudly attest to the many benefits of VR.

Download PDF: Click here to view the article.

The Schaefer Group Announces New Division Office

The Schaefer Group is pleased to announce effective March 1, 2019, the opening of a new division office for contracting and material sales in Knoxville, Tennessee. We will now be able to competitively and efficiently service all our southern customers in Tennessee, Alabama, North & South Carolina, Georgia, Virginia and Arkansas.

Eston Seay will be the Southern Sales Manager for this office. Eston has extensive foundry knowledge and over 24 years of experience wrecking-out and relining reverbs, launder systems, ladles, and induction furnaces. He has been with The Schaefer Group for 4+ years managing the Louisville, Kentucky district and servicing our customers in that area. With over 28 years of hands-on experience in the refractory contracting side of the business, he will be a great asset and able to assist you with all your furnace and operating needs. He will be reaching out to you in the near future and looks forward to working and meeting with each of you. It’s because of customers like you that The Schaefer Group continues to grow!

Eston Seay’s contact info:

Cell: 502-631-1962

Email: eston.seay@theschaefergroup.com

Benefits of Taking Your Melt Area into the 21st Century - (Simple Solutions That Work! September, 2018)

As I travel around the world seeing processes of all shapes and sizes, one thing becomes very clear – that melt shops are most often left out of any and all of the latest technology improvements.

Download PDF: Click here to view the article.

Molten Metal Management Back to Basics - (Simple Solutions That Work! April, 2018)

In my 37 years of traveling all over the world one thing has become increasingly apparent. Some die casters and foundries have lost the basic understanding of molten metal management. I have been asked to talk to companies about this subject more in the last three years than in all years combined with The Schaefer Group, Inc.

Download PDF: Click here to view the article.

Get Back to the Basics of Melting - (Foundry Management & Technology January 2018)

Reprinted with permission of Penton Media, Inc.

For aluminum foundries and diecasters, establishing the right processes will achieve high-quality metal consistently, improving results and reducing waste.

Download PDF: Click here to view the article.

Furnace Facts, ROI’s & Energy Use Numbers - (Simple Solutions That Work! September, 2017)

The ‘Ranking of ROI’ expenditures for aluminum furnaces, in other words, how to get the biggest bang for your bucks from quickest-to-slowest investment recovery.

Download PDF: Click here to view the article.

Why You Nees a Systems Integrator - (Simple Solutions That Work! April, 2017)

Where can you find someone who understands the data you need and how to display, capture and store it forever?

Download PDF: Click here to view the article.

Electrically Heated Immersion Element Holding Furnaces - (Simple Solutions That Work! Sept, 2016)

Immersion element aluminum holding furnaces available for over 10 years and are finally gaining in popularity with North American manufacturers. Asian companies were the first to use them in the US and now they have really taken off in the die cast and foundry world for important energy efficient, clean metal producing, and low maintenance reasons...

Download PDF: Click here to view the article.

Epcor Foundry Installs Schaefer Furnace

Epcor Foundry, a division of Seilkop Industries, recently installed a combination dry hearth and wet bath aluminum melting furnace from The Schaefer Group.

This gas fired furnace delivers degassed and filtered metal to the casting line – which gives Epcor the cleanest metal possible. The end opposite the dry hearth has a degassing unit and a filter with two electric elements in the ladle well end of the furnace, to maintain temperature stability during production.

"The Schaefer Combination Furnace gives Epcor the ability to produce higher quality parts more efficiently,” said Dave Seilkop, president of Epcor Foundry. “The unique ability of this energy saving combination furnace to also reduce metal loss with cleaner metal makes this an ideal choice for our aluminum part production,” he added. Installing the best equipment means producing better products at less cost for our customers – it's that simple!