Electric Aluminum Furnaces

Resources

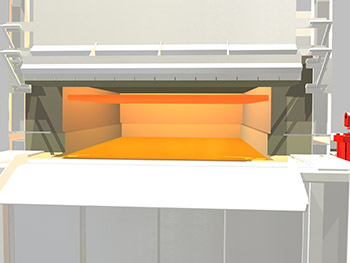

The Schaefer Group developed the world’s first electric reverbatory (wet bath) furnace in 1974 and the rest is history. This furnace is now the industry’s first choice for low cost production of clean molten aluminum. Our highly efficient electric reverberatory melting furnaces provide the best quality metal from ingot or scrap. And, they have an extremely low metal melt loss and are easy to operate and maintain. Melt loss is so low with this furnace (often less than 1%) that those savings alone typically provides a one year (or less) return on investment!

ADVANTAGES:

- Excellent Metal Quality – no combustion means no metal gassing and a conservatively-sized tranquil bath eliminates oxide-creating metal turbulence.

- Melting – silicon carbide resistance elements transfer radiant heat to the work load to melt metal with only 0.20 to 0.23 KWH per pound. You can even melt efficiently from a cold start. A full-proportioning control system delivers accurate energy flow.

- Melt loss – typically less than 1%.

- Cleaner heat – means a cleaner work space.

- Sustainability – no output of hot fuel gasses to heat up the environment means reduced carbon footprint.

FOR:

This versatile furnace meets the needs of a variety of metal casters, high and low pressure die casters, and permanent mold, sand, investment and lost foam foundries around the world.

OPERATION & MAINTENANCE:

- Low maintenance requirements – highest uptime operation on the market.

- Low metal melt loss

- No EPA permits required

- Quiet operation

Specs:

- Dimensions/footprint are available in our brochure.

Additional Considerations:

- Filtration, degassing, circulation, transfer methods

Options:

- Alarm thermocouples

- Premium lining materials

- Super insulated linings

- SCADA control data collection

- Filtration

- Degassing

- Electric meters