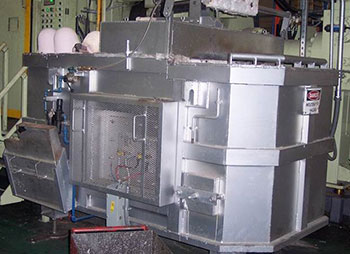

Ultra low energy (Gas/Electric) Holding Furnaces

Resources

Electric Holding Furnaces

A 2,000 pound (907.2 kg) Schaefer electric holding furnace will maintain a temperature of 1,300 degrees Fahrenheit (704.4 degrees Celsius) for only 3 KW/hr (2,581.2 kcal/hr) with well covers. Similar savings can be achieved with all capacities ranging from 1,500 (680.4 kg) to 30,000 pounds (13607.77 kg).

Gas Holding Furnaces

A 2,000 pound (907.2 kg) Schaefer gas holding furnace will maintain a temperature of 1,300 degrees Fahrenheit (705 degrees Celsius) with 50 to 60 CF gas/hr (12,660-to-15,120 kcal/hr). We can also supply a dual energy option that lets you convert between electricity and gas to use the lowest cost source.

We offer a choice of ni-chrome or silicon carbide heating elements. Ni-chrome lets you use a lower-cost control system; silicon carbide handles higher watt loads for more compact furnaces.

ADVANTAGES:

- Efficient holding of temperatures at low cost.

- Easily cleaned.

- Very little pick up of hydrogen in our gas fired units.

- Full proportioning controls means we connect more than you will ever need, but use only what it takes to maintain temperature!

FOR:

This versatile furnace meet the needs of a variety of metal casters, high and low pressure die casters, and permanent mold, sand, investment and lost foam foundries around the world.

OPERATION & MAINTENANCE:

- Lining – select either monolithic or board lining systems. Our rugged, thermally efficient, non-wetting lining allows us to place the hot metal well anywhere specified. And we can make it square or rectangular, straight or offset at special angles, even with sloped ends for robot ladling and other automation equipment. The lining also helps keep the casing temperature low.

OPTIONS:

- Power-operated tilt lid allows cleaning of the furnace in less than 10 minutes.

- Full-proportioning with solid-state microprocessor controls and specially-designed heating elements with a proven record of superior service life can be easily added.

- Alarm thermocouples

- Filtration

- Degassing with T Wands

- Molten Metal Circulation

- Inoculation

- Rotary Degassing